YG Paper Cup Production Line

Your One-Stop Solution for High-Quality Paper Cups

We focus on providing one-stop paper cup manufacturing solutions from design to finished products, covering every detail from printing, die cutting, paper cup manufacturing machines to final packaging and shipment.Whether it is catering, retail or home use, we can provide customized solutions to meet your various needs.

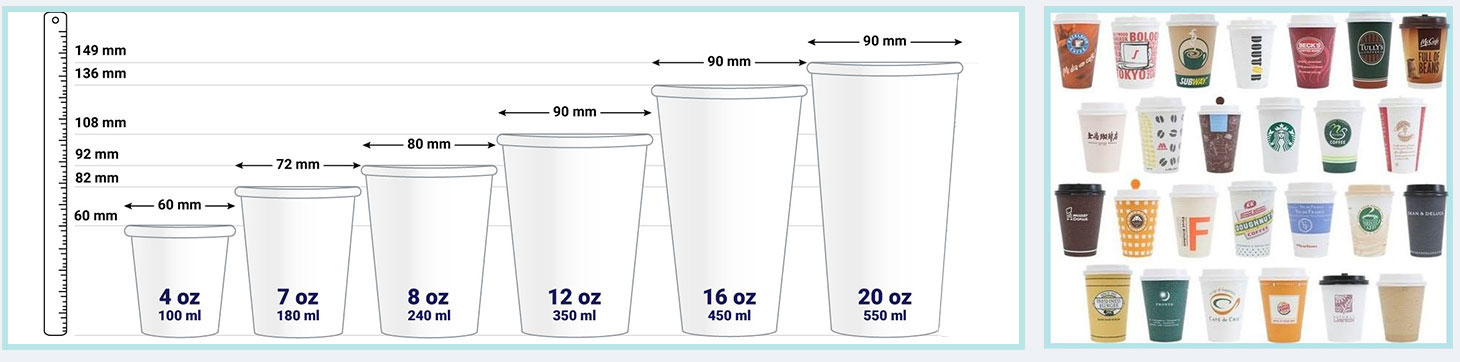

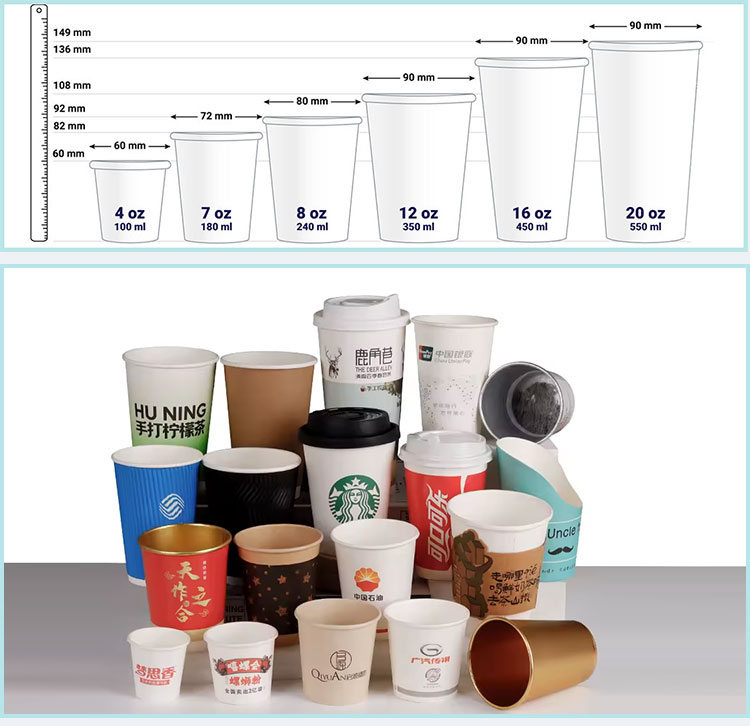

Paper Cup Sizes And Types

Our paper cup production lines are capable of manufacturing a wide range of sizes and types to meet diverse needs. Below are some examples: Different Capacities: 4oz, 8oz, 12oz, 16oz, and more. Different Types: Cold drink cups, hot drink cups, ice cream cups, popcorn buckets, and others.

Product Center

Printer Machine

Printing Width:850/950/1200mm

Features: Automatic feeding, automatic registration, automatic detection

Die-Cutting Machine

Die-Cutting Width:850/950/1200mm

Maximum die-cutting thickness: 1.5mm

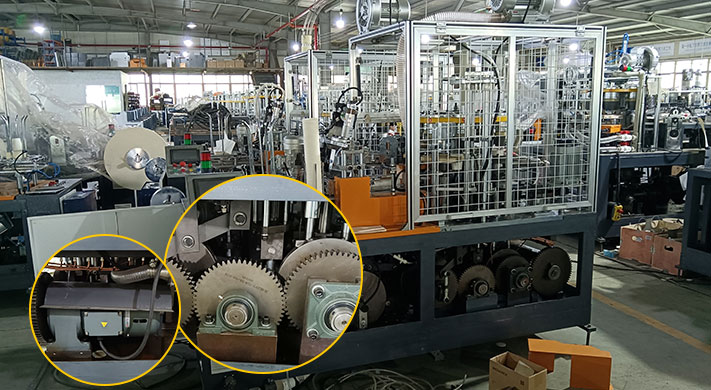

Paper Cup Machine

Capacity: 100-180pcs/min

Paper material: 160-350gsm

Automatic Packaging Machine

Why Choose Our Paper Cup Production Line?

High Efficiency, High Production Capacity

Production Speed: Leading market products can reach 100-180 pieces per minute, far exceeding industry averages.

Daily Output: Based on an 8-hour work schedule, daily output can reach 48,000 to 86,000 pieces, meeting large-scale production demands.

Automation Level: Fully automated production line, from raw paper to finished packaging, requires no manual intervention, significantly improving production efficiency.

Outstanding Machine Quality

Complete After-sales Service

Related Products

Customer Cases

YG Machinery’s paper cup production lines are trusted worldwide, serving clients in over 100 countries. From Chile to Malaysia, our machines deliver efficiency and reliability, empowering businesses globally. Join our success story today!

About Us

Get Solution & Quotation

.jpg)